Our partners visited the central office of Emmerre located near Turin, in the town of Settimo Torinese. There are commercial buildings, production and assemblage departments, quality observation station and warerooms.

.jpg)

Our partners, together with Emmerre co-owner Alessandro Markato, as well as export manager Mimmo Fina and sales manager in Ukraine Taisiya Sapozhnik at the central office.

It is worth noting the laboratory, where the frictional properties of material and geometric dimensions of parts are checked for compliance with the drawings. Parts are constantly coming here - selectively from each assembly. Specialists test the parts for compliance with various indicators, including the breakout power of pads. The products are also checked for visual compliance with the dimensions according to the new standards for product homologation in Italy.

.jpg)

Checking the geometric dimensions of the hub for compliance with the drawings

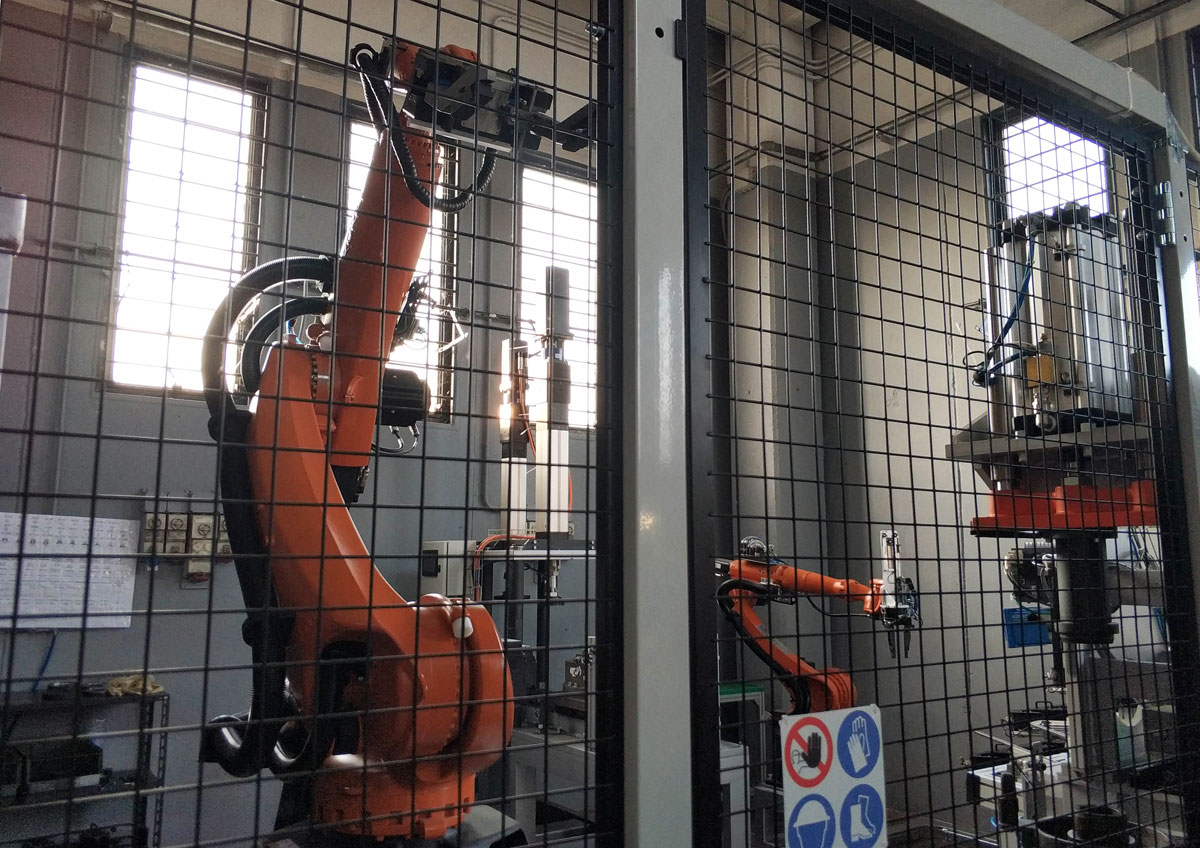

Our partners were most impressed by the new automated line, which recently began working in the assembling department. On this site, the bearings are pressed into the hubs autonomously, without intervention of employees. The strength and parameters of the press fitting on the line are controlled by special software. The application is also responsible for the work of two robots that perform basic functions: one with a pulse power of 350 kg controls the movement of the wheel hubs, the other controls the supply of components. Thanks to a sophisticated system, the entire section works autonomously, and the finished hubs exit the line. From here, every part without exception is transferred to the quality sector, where its technical characteristics are checked. After that, the appropriate marking is put on the hubs.

New robotic wheel hub assembly line complete with bearings and ABS wheel

In order to see the line in action, watch the video from the manufacturer.

A warehouse with finished products is also automated, and there are large-sized goods in one of the premises - disks, drums and hubs - are moved using a bridge crane with a magnet.

Automated warehouse of finished products, from which parts of the brake system, suspension and steering are shipped.

After the excursion, our partners had a wonderful entertainment program: guests visited the aquarium in Genoa, where they enjoyed the beauty of the underwater world, and on excursions in San Remo and Monte Carlo, they discovered the vibrant architecture and unforgettable flavor of Italy.

All partners had only wonderful impressions of the trip! Everyone enjoyed the gift of the promotional basis! And we are pleased to invite partners to participate in the following promotions and win gifts!